- Other Metal Processing Machinery[6]

- Other Construction Material Making Machinery[2]

- Plasma Welders[4]

- Other Machine Tools[6]

- Other Machinery[6]

- Welding Torches[5]

- Pipe Making Machinery[6]

- Tube Welders[1]

- Metal Cutting Machinery[1]

- Plastic Cutting Machinery[1]

- Other Construction Machinery[1]

- Other Welding Equipment[6]

- Manipulator[1]

- Other Welding & Soldering Supplies[5]

- Welding Tips[6]

- Metal Straightening Machinery[6]

- Arc Welders[6]

- Spot Welders[1]

- Conveyors[1]

- Contact Person : Ms. Liu Tina

- Company Name : Ningbo Jinfeng Welding And Cutting Machinery Manufacture Co., Ltd.

- Tel : 86-574-63487719

- Fax : 86-574-63487678

- Address : Zhejiang,Ningbo,Xinglu Village, Hangzhou Bay New Area, Cixi, Ningbo, P.R.China

- Country/Region : China

- Zip : 315336

Related Product Searches:XMH-1000 cantilever type submerged arc welding machine,High Quality,SUBMERGED arc welding machine, h beam welding machine,XMH-1000

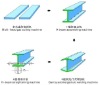

It includes:1) Multi-head strip flame cutting machine2) H I T beam assembling machine3) H I T Submerged arc welding SAW welding machine4) 90 degree Movable overturning machine5) 45/60 degreeHydraulic overturning machine6) Steel convoyer machine, H I T beam moving 7) 180 degree fliting overturning machine

8) Hydraulic/ H beam flange straightening machine

H beam shot-blasting machine

KG4000 CNC/Multi-head strip flame cutting machine

Rail span: 4000 mm Rail length: 14000 mm (can be extended)

Effective cutting width X Length: 80-3200 mm X 12000MMCutting speed: 50- 750 mm /min for gas cuttingRapid speed: 3000 mm /min Longitudinal strip cutting torch: 9 sets

CNC transverse cutting torch:2 sets

CNC control system: JF-CNC08C

Nesting software: FastCAM professional

1500 H beam automatic assembling machine

Beam web Height: 200 -1500 mm Web thickness: 6 -32 mm Beam flange width: 150-800mm Flange thickness: 6 -40mm Length of Beam: 4000 -15000 mm Assembling speed: 0.5-5.5 m/min (step less)

Input roller + Output roller: 24000mm

CO2 gas welder: 2 unit Panasonic KR350

MZG2X1000 × 2 Gantry submerged arc welding (SAW) machine

Beam web Height: 200 -1500 mm Web thickness: 6 -32 mm Beam flange width: 150-800mm Flange thickness: 6 -40mm Length of Beam: 4000 -15000 mm Rail span X Rail length: 4000x20000mm

Welding speed: 240 -1000 mm /min Rapid speed: 3000mm /min, doub le SideWelding position: fillet welding in the flat position

Submerged arc welder: 2 units, DC1000 Lincoln, USA

JZ-40 H beam flange straightening machine

Beam web Height: 200 -1500 mm Web thickness: 6 -32 mm Beam flange width: 200-800mm Flange thickness: 6 -40mm (St37, Q235 material)Straightening speed: 13000 mm /min

Input roller + Output roller: 20000mm Relationship between the width and thickness of the work piece

s | 20-30 | 30-40 |

b | 200-800 | 400-800 |

HPG1810 shot-blasting machine

Specifications of work-piece

Steel plate: Width<1800mm

Thickness 6-30mm

Length> 3000mm

Section steel: max section size (width×height) ≤1000×1800mm

Steel tube, angle steel, C-channel, I-beam and H Beam: length ≥3000mm

Steel structure: max section size (width×height) ≤800×1600mm

Length ≥3000mm (work piece that could be running on the conveyor)

Shot-blasting quality grade:ISO850-1: 1988 A-B Sa2-Sa2.5 grade

Work-piece processing speed: V=0.6-3.0m/min

Total capacity: about 130.4Kw.

XMH-1000 cantilever H-type steel submerged arc welding machine is a manufacturingdevice developed by our company to weld H-type steel on the basis of market demandand absorbing know-how of domestic and overseas similar product. This machineis mainly applied to H-type steel submerged arc welding, especially good for large-scaleH-type steel submerged arc welding. The machine features compact structureand easy operation.Product main featuresThe machine in the mass adopts the structural configuration of cantilever loop wheelmachine drive, mainly composed by driving travel gear, console system, pneumaticcolumn elevating mechanism, cable pneumatic column level travel mechanism,arc guide mechanism, welding flux reconditioning system, automatic submerged arcwelding system, electric operating system etc. Loop wheel machine is driven byfrequency conversion motor drive system, and consequently drives arc guide mechanismto move steadily. As spring stretching mechanism functions, the arc guide mechanismforces arc guide wheel to move along arc welding seam. When the columnis conducting large-scale adjustment, the elevating mechanism and level travel mechanismis easy to operate . welding flux reconditioning system can fully and effectivelyrecover welding flux and send it into segregator for filtration(removinguseless dust), and realize its recycling.Main technical parameter1.Wing panel width: 200-800mm2.Web height: 200-1500mm3.Wing panel thickness:6-40mm4.Web thickness:6-32mm5.Welding speed:350-750mm/min (according to welding procedure)6.Machine table speed: <2500mm/min7.Welding position: arc welding8.Dimension of welding wire used: DIA3.2-5mm9.Principal machine power: 55ow(exclusive of welding machine)

XMH-1000 cantilever type submerged arc welding machine